About Series 100

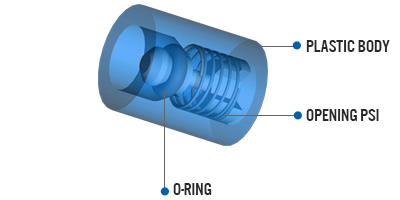

Used for liquid or air, our cartridge check valves can be incorporated into virtually any mounting style. They are easily inserted into fittings, manifolds, or installed in-line. Available in standard or manual relief bleed styles, Series 100 Standard Check Valves and/or Pressure Relief Valves range from 1/4" to 3/4" sizes and opening pressures from 0.09 to 20 PSI. At Smart Products USA, all of our valves are customizable by plastic body material, o-ring material, and opening spring pressure to meet a specific application criteria. Series 100 also offers specialty styles in barbed, NPT, side seal, and flanged - click here to view these options.

Contact Us!

Drop us a line, and we'll get back to you quickly! Fill out the form or call 1-800-338-0404 for more information.